AM Transformers

High Wycombe

Manufacturer, designer & supplier of high quality,

reliable custom main and three phase transformers

Manufacturer, designer & supplier of high quality,

reliable custom main and three phase transformers

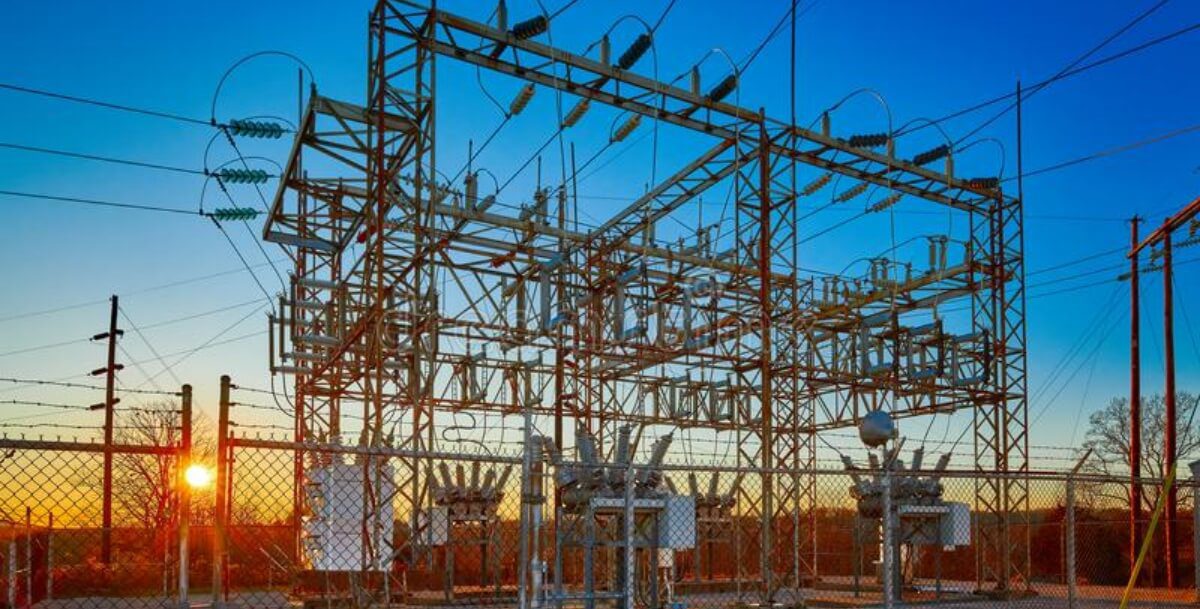

Custom Industrial Transformers Supplying Power Transformers Worldwide First Choice for Mains & Three Phase Transformers.

AM Transformers are UK transformer manufacturers and distributors of quality transformer products.

✓ Manufactured to International and UK safety standards.

✓ Superfast despatch & delivery on 3 Phase Transformers & other Transformers.

✓ Custom Transformers design and manufacture service.

✓ Free Technical Support from Experienced Technicians on All our Products.

✓ Advice & Guidance on sector specific solutions across a number of Industries.

We can supply a broad range of transformer types in any quantity.

Suitable for a wide variety of uses. If you are unsure of what transformer type would best suit your needs, then our technical department will be happy to advise you on the best transformer type to fulfil your requirements.

We can provide single phase transformers & three phase transformers, encapsulated transformers, high power transformers, custom designed transformers, toroidal transformers, communication & modem transformers, audio transformers, ac/dc adapters, ac/ac adaptors, dc/dc converters, chassis mounting transformers, PCB transformers, inductors & chokes.

The list goes on. For a more comprehensive guide to our transformer range, please view our products pages.

In addition to our range of mains transformer products, we are pleased to be able to offer a power supply subassembly service and a power supply PCB Manufacturing service.

Technical support is available for all our products. Our team will be pleased to answer any questions you may have and guide you through any problems you may have. If you have any questions please do not hesitate to contact us. Dimensions & specifications may change without notice.

Great company to order from! Were very reliable throughout the whole process. 😀

Flawless purchase along with great end result.

I have seen a huge boost in the productivity since I bought the EMI Line Fitter, well worth it.

I recently bought an AVR and can say with 100% approval that this is the best AVR I have used and ever seen on the market.

Very good communication before and after purchase. AM was very reliable over email and gave me some very important details

A massive thank you to AM-Transformers. I feel very relieved that I was able to purchase my product from this diligent and cooperative company.

Give our sales team a call and let’s discuss your requirements